Designed to deliver: How collaboration created an award-winning device that puts patients first

on LinkedIn:

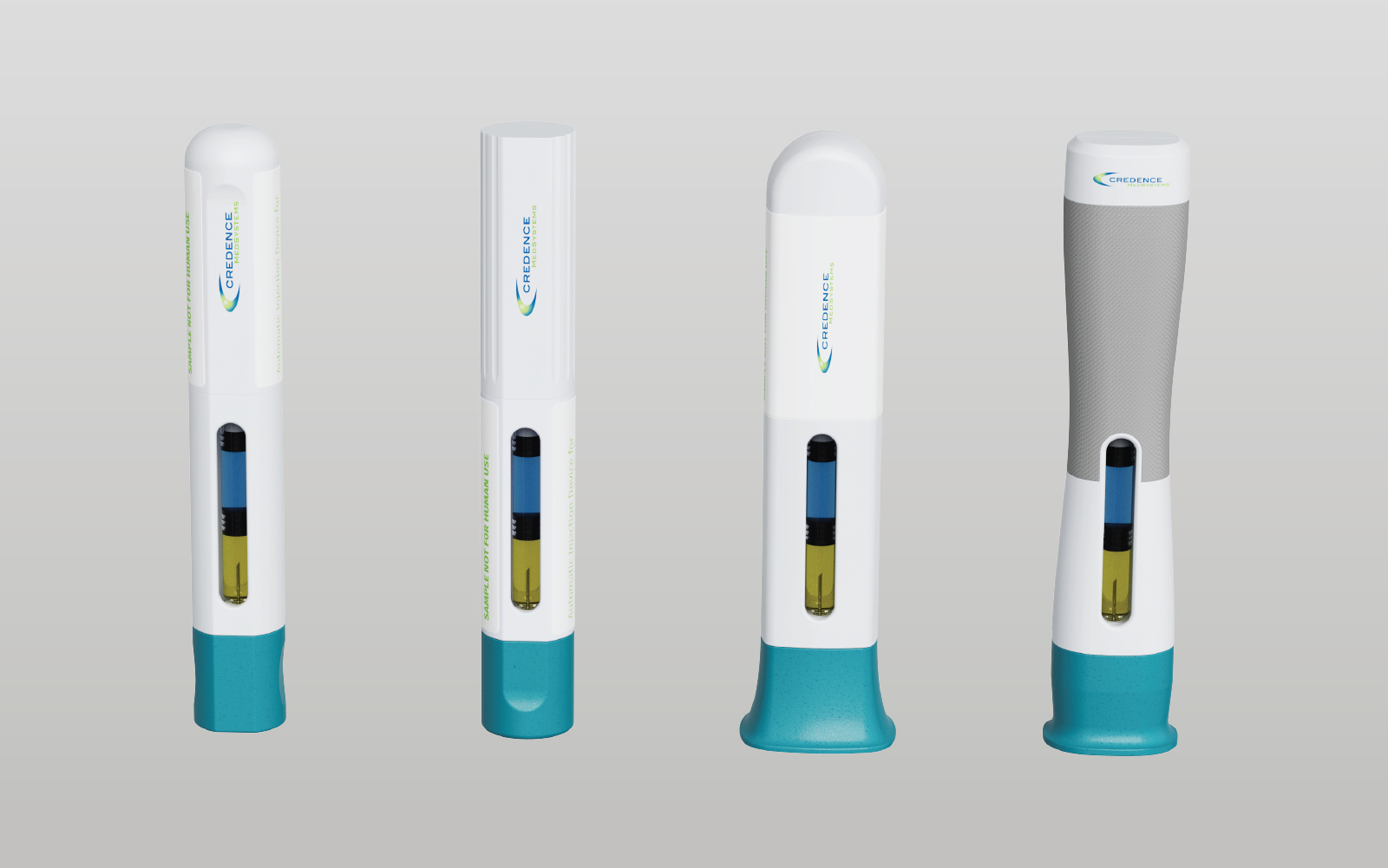

When Credence MedSystems set out to build on the capabilities of their Dual Chamber Syringe System (DCSS), they weren’t just looking to adapt it – they wanted to expand its potential. Together, we set out to create a new platform for at-home, sequential-drug delivery: one that combined human-centered design, deep technical know-how, and the power of partnership. Over the course of the project, our teams worked together to bring that vision to life. The result? A Red Dot 2025 award-winning demonstration autoinjector that not only showcases the functionality of the DCSS, but also reimagines how two drugs can be delivered at home in one simple injection.

Three Ingredients for Award-Winning Device Design

1. End-to-End Expertise

This project brought together two areas of specialist knowledge. Credence brought the core technology: a dual-chamber syringe system with automatic needle retraction that uses standard glass components, designed for sequential delivery of two formulations. Our team contributed deep experience in autoinjector design, usability, and manufacturing engineering, translating complex drug delivery requirements into devices that are safe, manufacturable and easy to use.

2. Close Collaboration

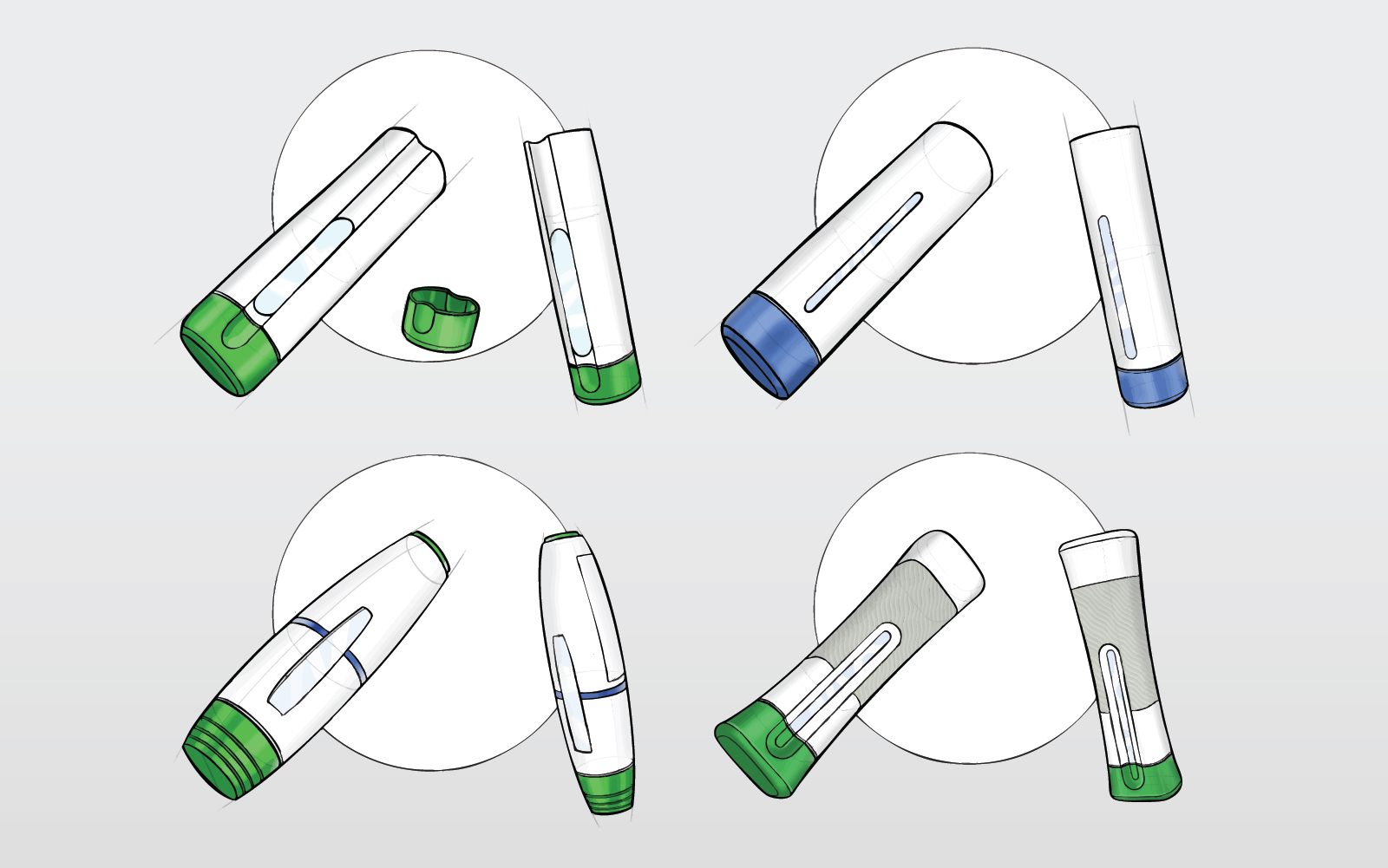

This was a shared, iterative development process built on close collaboration. From the outset, the teams worked together to define key requirements and align on a shared vision. By combining Credence’s knowledge of their container system with our insight into autoinjector mechanisms and user experience, we were able to accelerate from concept to working demonstration.

We shaped the engineering and design direction through regular feedback loops, with both teams actively involved in decision-making throughout. When the Credence team visited our site in Cambridge, UK, we held a hands-on working session to evaluate both functional prototypes and industrial design handling models. Together, we assessed the feel of device activation, form factor, and visual cues, blending technical and aesthetic considerations to arrive at the perfect overall experience.

The feedback was immediate. One mechanism was described as “smooth as butter”, a clear signal that we were on the right path.

3. Built-in User-Centered Thinking

While the request was to develop a reloadable, robust model for demonstration purposes, the long-term goal was always to support at-home use. We designed the experience to closely emulate the familiar, two-step workflow of a single-chamber autoinjector, while delivering the additional benefit of dual-drug administration. In addition, while the demo unit was made reusable and resettable for hands-on use, it was developed with a clear development pathway towards a single-use, commercial device.

We also considered communication and clarity from the outset; exploring iconography, leaving space for regulatory labeling, and ensuring the device visually conveyed key aspects of the user benefits.

Platform Flexibility

What makes this device stand out isn’t just the sequential delivery of two formulations. It’s the fact that the same primary container can be used across both prefilled syringe and autoinjector formats without changing any drug-contacting components. That kind of flexibility reduces development burden, simplifies supply chains and makes it easier for pharmaceutical partners to scale and adapt their delivery format over time. There’s also a clear benefit for patients: fewer injections, simpler instructions, and added confidence that both parts of the treatment are delivered, every time. Beneath it all lies a sustainability advantage. With a sequential delivery device, there’s only one autoinjector to manufacture, ship and dispose of, which can make a meaningful difference at scale.

This wasn’t just a concept exercise – it was a real-time demonstration of what’s possible when two expert teams bring their strengths to the table. We developed a fully-functioning demo platform and in doing so, also laid the groundwork for future commercial evolution, including a clear view of what it would take to move from demo model to single-use device.

It’s a testament to the momentum, shared focus and technical excellence that powered this collaboration and we’re proud to see that work recognized with an industry award.

Get in touch

This project showed what’s possible when deep technical expertise meets close collaboration and how the right partnership can bring a new device vision to life. If you’re looking to explore what your delivery system could become or want to create a new device experience that puts patients first, we’d love to help.

Fran Pencliffe

Healthcare Device Engineer