Case Study | Unilever

Smart growth for soft ice cream market

Soft ice cream is a large and growing segment of the global ice cream market, and Unilever wanted to expand their offering. The global leader had a novel cartridge that neatly avoided the hygiene challenges traditionally associated with this category, but they needed a semi automated refrigerated dispenser for smaller retailers, restaurants, and entertainment venues.

A market trial was planned but their prototype had technical challenges. Unilever knew that resolving these with a manufacturing partner this early in the project might overly constrain the design, so they asked us to help.

Our Approach

To address the problems, we implemented elements of Potential Realised ™, our phased approach to product development. First Root Cause Analysis was used to identify and scope the key challenges in function, usability and cleanability, and we applied our broad-based technical team to quickly develop and test solutions. These were integrated into a ‘technology demonstrator’ only three months into the project. Once fully tested we moved on to design a prototype suitable for low-volume manufacture.

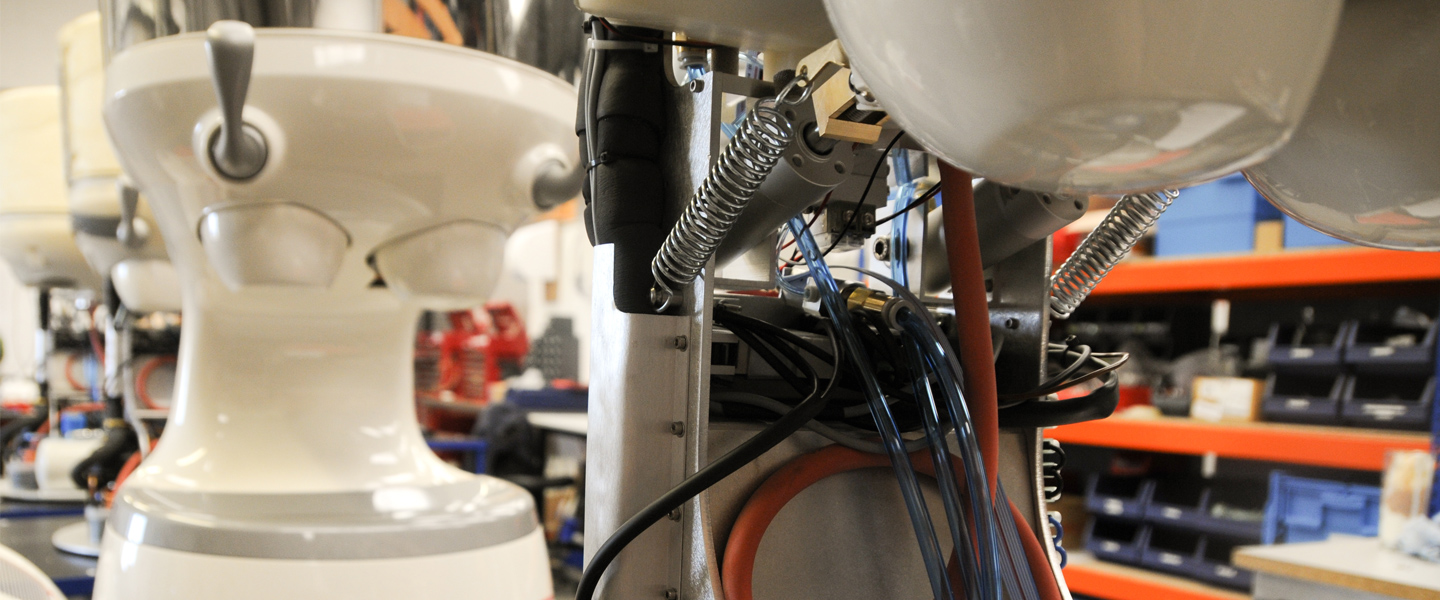

We set about creating tooling and a small manufacturing facility for a batch of 50 dispensers for the field trial. The aim was to manufacture units with a fit, finish, and function indistinguishable from future production machines. Of course, the refrigerated dispensers had to be safety tested, meet appropriate CE standards and be shipped to very tight timescales.

We also added connectivity to each machine together with a cloud-based database and user interface to help Unilever manage the supply chain and to monitor sales and maintenance.

The value we created

The world’s biggest ice cream manufacturer was able to successfully deploy 50 appliances in outlets across Europe for a summer season in order to gather high-quality feedback on their new ice cream offer. This allowed them to make an important investment decision to grow their Heartbrand.

Though the units were prototypes, the 50 connected, refrigerated dispensers we built looked and worked reliably just like the real thing.