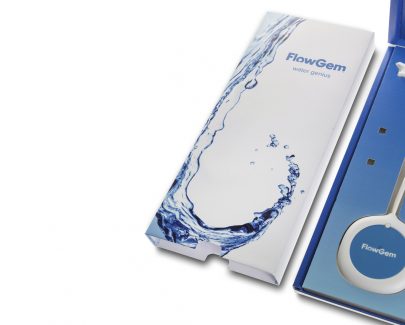

Case Study

From prototype to point of care PCR testing system, fast

We designed and tested over 100 improvements to our client’s instrument in just five months, enabling rapid iteration and scaled-up production. In addition, our team manufactured 45 units and generated the device history records needed to gain a CE Mark.